Loading...

Spur Gear Transmission

Design & Fabrication Course Contest

Project Details

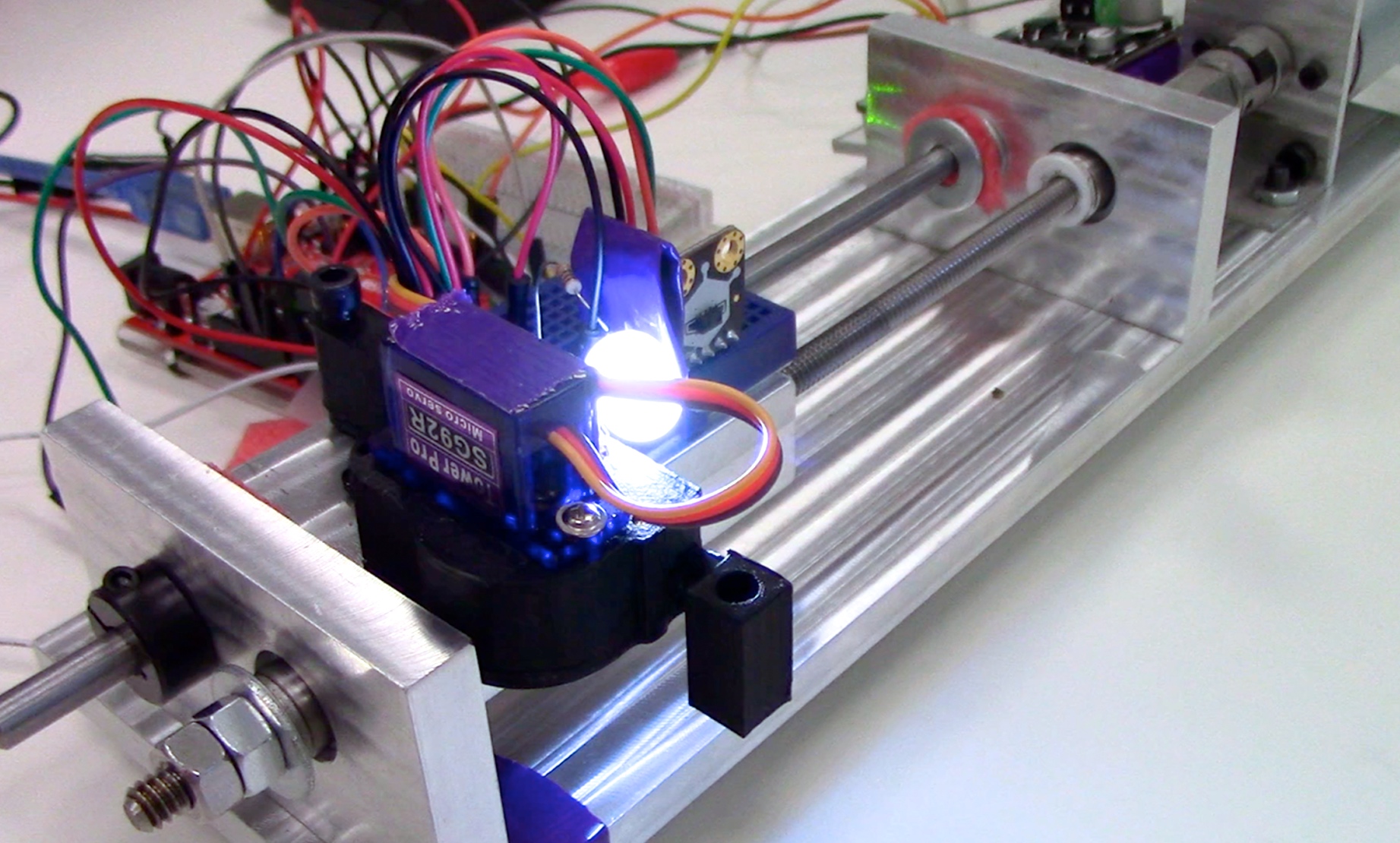

Given a budget of $150 and access to the ME lab, we worked in teams of 3 to design and fabricate a transmission that could increase the torque output of a DC motor to turn a bike wheel as fast as possible.

Our design featured metal hub gears to fit a gear ratio of 6.76, ball bearings, and a top acrylic plate in addition to the base to increase stability. My role in the fabrication process was making the acrylic walls.

Out of 10 teams, our transmission achieved the highest peak power and steady state power, and second highest peak RPM (right after the team who used a similar design, but plastic gears).

- Date: May 2017