Autonomous Product Locator

Project Details

Factories and warehouses are quickly converting to completely autonomous systems. In recent years, Amazon gained the spotlight for using Kiva robots to autonomously pack and process warehouse items. For these large scale commerce companies, there is a strong interest in shipping products at any time of day, any day of the year. Our robot tackles the issue of distinguishing between nearly identical products on the shelf.

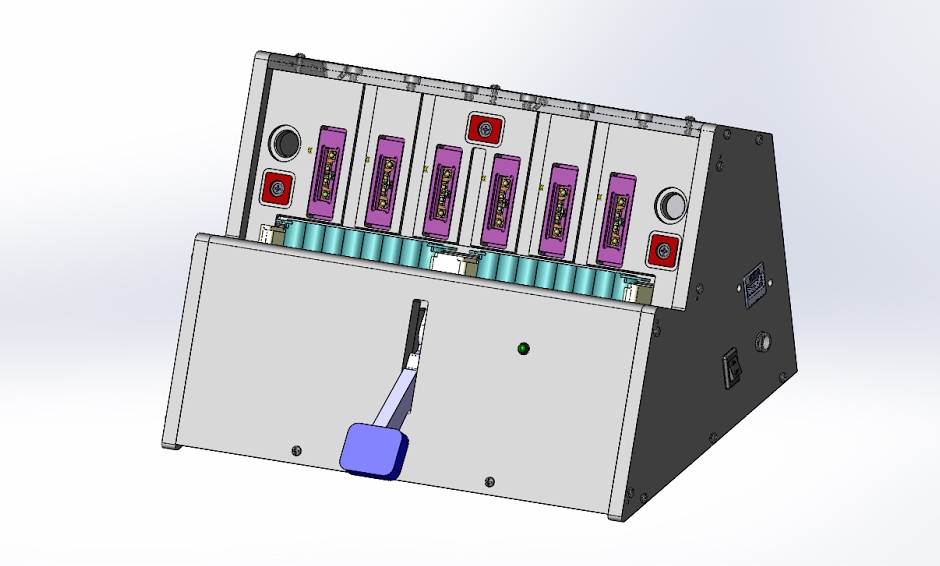

We designed and fabricated a device that moves across a shelf using a motor and lead screw, recognizes objects based on color, and pushes the selected object using a 3D-printed linear actuator. Our approach distinguished objects using color, but the RGB sensor could easily be replaced with a barcode scanner for actual warehouse applications. All aluminum parts were machined ourselves on the mill. The RGB sensor, servomotor, bidirectional motor-controller, and IR sensor were controlled using Arduino.

- Date: June 2017